Going net zero will be the world’s biggest task in in the coming decades. Today, commercial vehicles like medium and heavy duty trucks accounting for roughly a quarter of carbon emissions in the transportation sector. Manufacturers are turning to lightweight solutions to lower emissions and increase efficiency. GF is a pioneer in this area thanks to its strong expertise and the ideal combination of design, materials and manufacturing processes.

GF Casting Solutions is helping customers worldwide with its innovative, lightweight automotive parts. These include assembly brackets, for example, made of new high-tech alloys adapted for special use cases and properties, such as strength or heat resistance, instead of ordinary iron. In China, where ambitious emission targets have been officially set, GF is working with leading truck maker Sinotruk on the construction of next-generation vehicles that meet some of the world’s strictest emission standards.

Since 2015, GF Casting Solutions’ Kunshan plant, some 60 kilometers west of Shanghai (both China), has been supplying Sinotruk with a series of lightweight parts that have brought weight reductions of around 15–20 percent compared with the previous components, including bogie anchorages, cross beams and various types of brackets. The weight reductions have helped Sinotruk become more competitive in its domestic market with new trucks that both reduce harmful emissions and are cheaper to operate.

“China has committed to reaching its carbon emission peak by 2030, which means cutting emissions is a must for industries across the board.”

Richard Zhang, Deputy Head of R&D Asia at GF Casting Solutions

Trusting relationship despite tight deadlines

“The Chinese market evolves very quickly, and new trucks need to be developed and built in about six months,” says Richard Zhang, Deputy Head of R&D of Product Development at GF Casting Solutions China. “We need to deliver in only half of the time we would normally have.” That means many busy weeks – but Zhang says GF’s strong R&D capabilities and production capacity have enabled the company to meet even the tightest schedules, giving the company a clear advantage in China’s commercial vehicle market.

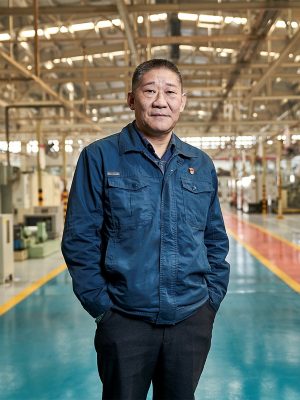

“I’ve worked on multiple projects with GF, and it is definitely one of the most reliable suppliers I’ve seen,” says Feng Shi, a 30-year veteran at Sinotruk and currently the lead buyer of casting parts. “GF provides us with strong R&D support and machining expertise. We have built a very trusting relationship.”

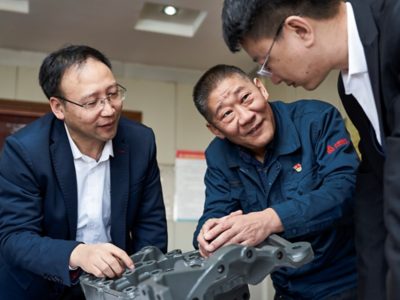

According to Richard Zhang, that trust is hard-earned. The initial contact with Sinotruk was made in 2012, and the cooperation started gradually, initially with smaller projects. “They wondered if we could deliver new, original designs, not just improvements on the old ones – and we did,” Zhang says.

The breakthrough in innovations

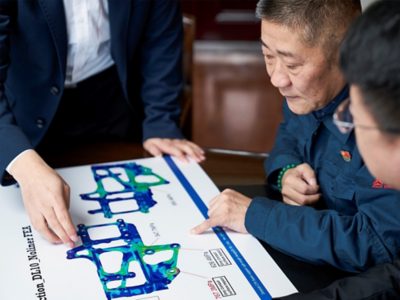

The partnership reached new heights when Sinotruk asked GF to design the new assembly bracket for its flagship truck Howo-T7H in 2017. “Through structural optimization, mold flow and casting technology analysis, we provided Sinotruk with a new part that weights 25 percent less,” says Ethan Tian, Account Manager at GF Casting Solutions. The success helped lay a solid foundation for future cooperation. More than a dozen new products are currently in the development pipeline, Tian adds.

Looking ahead, both Tian and Zhang see tremendous opportunities to increase GF’s collaboration with other commercial vehicle manufacturers: “We have the technological foundation, and we are moving very quickly to enable our customers to shape future industry trends,” Tian says. Lightweight components from GF Casting Solutions will continue to contribute to the reduction of CO2 emissions worldwide, helping transform the mobility sector for many years to come.

Since 2015, GF Casting Solutions’ Kunshan plant, has been supplying Sinotruk with a series of lightweight parts that have brought weight reductions of around 15–20%.

“At Sinotruk, they wondered if we could impress them with original designs – and we did.”

Richard Zhang, Deputy Head of R&D Asia at GF Casting Solutions in Kunshan, Jiangsu (China), joined GF in 2005

Two Points of View

Why does China’s commercial vehicle market hold great potential for GF Casting Solutions?

Richard Zhang: China has committed to reaching its carbon emission peak by 2030, which means cutting emissions is a must for industries across the board. Demand for cleaner and more economical trucks will spike in the coming years and GF is in a great position to capture that growth. Some years ago, Chinese truck makers were asked by the government to make their products lighter. Not only to reduce emissions, but also because of highway fees. For instance, due to strict limits for overloading, GF’s innovative and lightweight design for casting solutions additionally helps the truck owners to avoid possible fees related to weight.

Which challenges do you see in this market and how are you tackling them?

Richard Zhang: First, you need to earn customers trust, then you need to be flexible and react quickly to customers’ needs. China is a fast-moving market, meaning that our internal system has to get the job done quicker, without compromising on process and quality.

“I’ve been working on multiple projects with GF, and it is definitely one of the most reliable suppliers I’ve seen.”

Feng Shi, Lead Buyer of Casting Parts at Sinotruk in Jinan, Shandong (China), at Sinotruk since the early 1990s

Why did Sinotruk choose GF Casting Solutions as its supplier?

Feng Shi: GF has a global reputation. Its state-of-the-art R&D capabilities can greatly help us with forward-looking lightweight designs. It’s also a very dedicated partner that we can rely on in challenging scenarios.

What has impressed you the most about GF during your cooperation?

Feng Shi: We know GF is a global brand with a very long history and mature management system. However, what impressed me the most is how agile and flexible the GF team is when it comes to finding innovative solutions within tight deadlines. It highlights how GF always puts the focus on the customer.

GF is working with leading truck maker Sinotruk on the construction of next-generation vehicles.

GF is working with leading truck maker Sinotruk on the construction of next-generation vehicles.

The initial contact with Sinotruk was made in 2012, and the cooperation started gradually, initially with smaller projects.

The initial contact with Sinotruk was made in 2012, and the cooperation started gradually, initially with smaller projects.

The partnership reached new heights when Sinotruk asked GF to design the new assembly bracket for its flagship truck Howo-T7H in 2017.

The partnership reached new heights when Sinotruk asked GF to design the new assembly bracket for its flagship truck Howo-T7H in 2017.

The success helped lay a solid foundation for future cooperation. More than a dozen new products are currently in the development pipeline.

The success helped lay a solid foundation for future cooperation. More than a dozen new products are currently in the development pipeline.

- ZeroGF

- ZeroGF

- ZeroGF

- ZeroGF